Reshmi Industries to unveil Advanced Winding Solutions for Post Spinning & Sewing Thread applications

The global textile industry is standing at a crossroads, where efficiency, sustainability, and intelligent automation have become imperatives rather than aspirations . Headquartered in Coimbatore, the textile hub of India, Reshmi Industries embodies the spirit of “Make in India, Make for the World” through its world-class solutions for post-spinning and sewing thread applications.

Vishnu Sajan, Joint Managing Director

With a heritage defined by resilience, relentless innovation, and customer-first thinking, the company today commands an enviable leadership position in the Indian market while steadily expanding its international footprint. As Reshmi prepares to take center stage at ITMA ASIA 2025 in Singapore, it is poised to reinforce its reputation as a technology powerhouse, unveiling a new range of high-technology machines driven by automation, AI, and sustainability.

ULTIFLEX DDSW Precision Soft Winder

Innovation as the Bedrock of Growth

At Reshmi, innovation is not a seasonal pursuit; it is the foundation on which the company has built its legacy. The management has consistently invested 7–8% of its annual turnover in R&D, a figure that underscores its commitment to staying ahead of the curve. This forward-looking approach ensures that Reshmi’s product lines are never static but evolve continuously to match the demands of a rapidly transforming textile industry.

“In today’s dynamic market, consistent R&D is not optional—it is essential. Automation is not just a value-add; it is the only sustainable way forward,” says Mr. Vishnu Sajan, Joint Managing Director. His words capture the philosophy that drives Reshmi’s relentless pursuit of smarter, more efficient, and user-friendly solutions.

PRECITHREAD PT2T Automatic Finish Winder

The Technology Team at Reshmi are not just building machines; they are anticipating the challenges of tomorrow—whether it is labor shortages, rising production costs, or the global push toward sustainability.

Featured At ITMA Singapore

49 Series –

Launched at ITMA Milan 2023, The 49 Series is a high performance electronic grooved drum winding machine for Soft Winding and Rewinding applications . Blending cutting edge technology with the simplicity and low maintenance advantages of traditional systems .It is equipped with Automatic Tension control system as standard. The latest upgrade introduces a pneumatic cradle pressure system that ensures uniform package density and winding quality across all spindles , critical for downstream process . With a single-point air pressure control replacing mechanical parts , it offers faster operation, improved reproducibility , and the lowest density variation in both conical and cylindrical packages.

49 SERIES RRW Electronic Grooved Drum Winding Machine

Ultiflex TG/TGAW

The Ultiflex TGW Is a precision package winding machine designed for a wide range of yarns including staple fibres and continuous filament , for both dye package and rewinding applications . Among its standout features are the electronic yarn laying system with flexible traverse, a positively driven bobbin for enhanced control, and an advanced pneumatic back pressure system that guarantees uniform package formation. It also includes online tension control, quick take-up change mechanisms, and Automatic Doffing

The TG-AW is a precision assembly winder that delivers packages of the highest density with minimal breaks , ensuring maximum efficiency in the subsequent twisting phase . For applications involving bare elastomeric yarns , The TG-AW can be optionally equipped with a positive unrolling device motorised by a brushless motor , enabling controlled unwinding with electronic draw ratio settings via the Touch Screen . The TGAW will be exhibited at ITMA Singapore with Automatic doffing system .

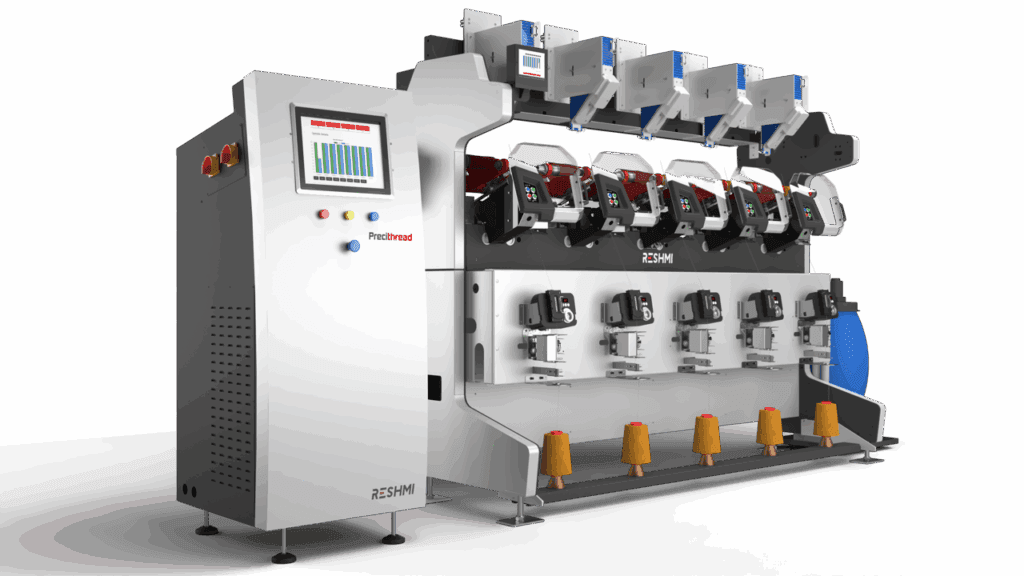

Precithread PT2T

The Precithread PT2T is the latest addition to Reshmi’s Highly successful Precithread product line, This High performance winder for cops/tubes is equipped with an advanced doffing magazine design that uses a false start system to ensure flawless tube loading , eliminating one of the most common issues faced by High speed Winders . Other outstanding features included a shorter doffing cycle , Tuck in System , best-in-class length measurement accuracy , an electronic lubrication system , and working speeds upto 1250 m/min – Delivering unmatched performance and reliability . With the Optional Auto-packing system , the PT2T transforms into a complete automatic winding solution , while the integrated R-Link IoT Solution enables real-time production monitoring , making it truly future-ready.

Ultiflex DDSW : Precision Soft Winder

As the saying goes, “Well wound is half dyed,” and Reshmi’s Ultiflex DDSW lives up to it by delivering perfectly uniform density within and between soft packages, ensuring the best results in downstream dyeing processes. With centralized controls that minimize manual intervention, the machine combines advanced features such as flexible winding ratio and crossing angle, automatic yarn unwinding tension control via sensors, pneumatic cradle pressure regulation, and proven counter-rotating blade technology for all types of spun yarns. The result is precision winding with unmatched consistency and efficiency

Customer Experience Centre: Setting a New Benchmark

In 2024, Reshmi inaugurated a state-of-the-art Customer Experience Centre in Coimbatore, a milestone that has redefined customer engagement in the textile machinery sector.

ULTIFLEX TGAW Precision Assembly Winder

This interactive hub goes far beyond the traditional showroom concept. Here, customers can witness live demonstrations of machines in operation, participate in technical workshops, and explore customised solutions tailored to their production challenges.

By enabling customers to test winding solutions and experience the machines firsthand, the centre serves as a powerful tool for building trust and strengthening relationships.

Global Markets: Expanding the Footprint

While India remains Reshmi’s largest and most important market, the company has steadily expanded its global presence. Its products are now trusted in diverse geographies, including Indonesia, Turkey ,Egypt and Southeast Asia, where mills are under increasing pressure to modernize with efficient and sustainable machinery.

The large-scale adoption of Ultiflex in Indonesia is just one example of how Reshmi’s reputation has transcended borders. By delivering international quality at competitive costs, the company has positioned itself as a preferred partner for textile majors worldwide. This dual focus—domestic dominance and international expansion—is what sets Reshmi apart as a true global player.

From India to the World

The story of Reshmi Industries is, in many ways, the story of modern India’s manufacturing resurgence. From a strong domestic base to global recognition, from pioneering IoT-enabled solutions to AI-driven automation, the company has consistently raised the bar for textile machinery.

With its Ultiflex TG set to debut at ITMA ASIA 2025, Reshmi is once again signaling to the world that the future of textile machinery is being shaped in India. More than a machinery maker, Reshmi has become a technology partner, innovation leader, and global ambassador of Indian engineering excellence.

As the global textile industry navigates a future defined by sustainability, automation, and digitalization, Reshmi Industries stands ready—not just to adapt but to lead.

Subscribe to Textiles Review

Get the latest posts delivered right to your inbox