Asahi Kasei Showcases PFAS-Free Polyamides, CFRP Recycling

Japanese technology leader Asahi Kasei is set to unveil its latest breakthroughs at K 2025, the world’s premier trade fair for plastics and rubber, from October 8–15, 2025 in Düsseldorf, Germany (Hall 8a, Booth E23).

A major highlight is the company’s PFAS-free polyamide and its innovative recycling technology for recovering continuous carbon fibers from CFRP (carbon fiber reinforced plastics) pressure vessels used in automotive applications. Using electrolyzed sulfuric acid, the process fully decomposes the resin matrix while retaining the carbon fibers’ original strength and continuous structure. Unlike conventional recycling methods that produce chopped fibers, this solution allows perpetual recycling of high-quality, cost-efficient continuous carbon fibers, with over 200 meters of recycled fibers on display at the event.

Asahi Kasei will also present PA and SEBS compounds reinforced with bio-based cellulose nano fibers (CNF) derived from cotton linter. CNF-reinforced polyamides feature high heat resistance, network-forming ability, and shear-thinning behavior, making them ideal for 3D printing, offering dimensional precision, smooth appearance, and strong mechanical performance. CNF-reinforced SEBS offers adjustable softness, low warpage, hydrolysis resistance, and broad applications, including jigs, tooling, and prosthetic devices.

To meet the growing demand for sustainable materials, Asahi Kasei will introduce its PFAS-free low-friction LEONA™ polyamide in Europe, boasting similar properties to fluororesins, making it suitable for sliding applications in automotive, robotics, office automation parts, and sporting goods.

Comparison of optical performance of AZP and conventional optical polymers

The company will further display solutions for lightweighting and streamlined automotive part production, including transparent polymer AZP™, designed to reduce birefringence in optical components such as AR/VR devices and head-up displays. An interactive automotive demonstration will showcase its role in next-generation HUD systems.

Comparison of optical performance of AZP and conventional optical polymers

The company will further display solutions for lightweighting and streamlined automotive part production, including transparent polymer AZP™, designed to reduce birefringence in optical components such as AR/VR devices and head-up displays. An interactive automotive demonstration will showcase its role in next-generation HUD systems.

SEBS for automotive interior surfaces

Additionally, SEBS materials enable single-step molding of skin and foam layers in automotive interiors, eliminating adhesives, reducing materials used, and improving recyclability. SunForce™ mPPE particle foam will be showcased for mass production of complex, thin-walled parts with superior heat stability and flame retardancy, ideal for thermal management in electronics, battery trays, HVAC insulation, and FRP cores.

SEBS for automotive interior surfaces

Additionally, SEBS materials enable single-step molding of skin and foam layers in automotive interiors, eliminating adhesives, reducing materials used, and improving recyclability. SunForce™ mPPE particle foam will be showcased for mass production of complex, thin-walled parts with superior heat stability and flame retardancy, ideal for thermal management in electronics, battery trays, HVAC insulation, and FRP cores.

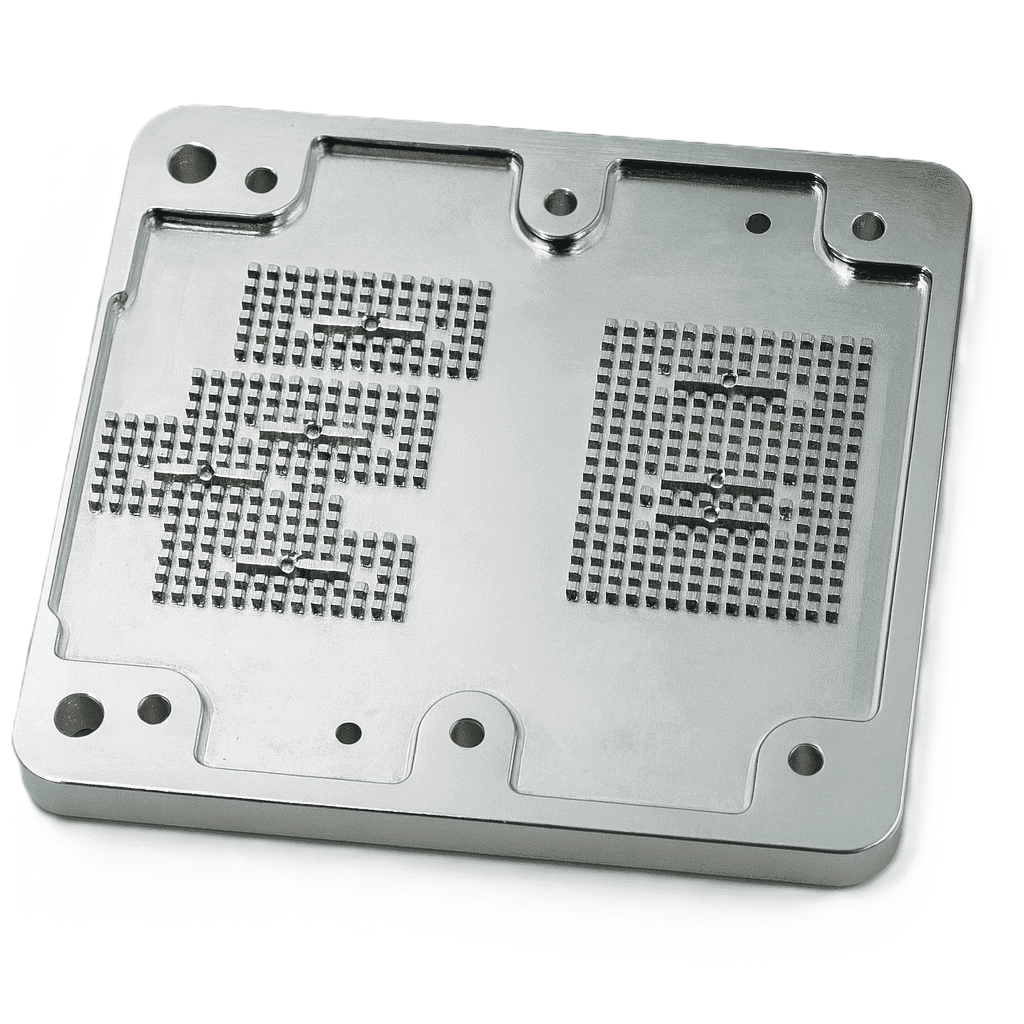

XYRON Slotted waveguide array antenna

Finally, Asahi Kasei will highlight mPPE XYRON™, enabling cost-efficient mass production of slotted waveguide array antennas for automotive millimeter-wave radars by replacing time-consuming metal milling with injection molding.

XYRON Slotted waveguide array antenna

Finally, Asahi Kasei will highlight mPPE XYRON™, enabling cost-efficient mass production of slotted waveguide array antennas for automotive millimeter-wave radars by replacing time-consuming metal milling with injection molding.

Subscribe to Textiles Review

Get the latest posts delivered right to your inbox